Loading an (Almost) Obsolete Cartridge

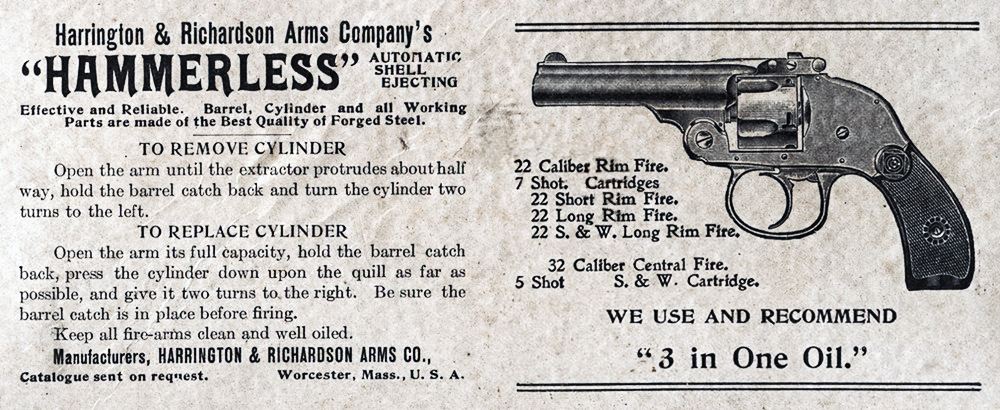

I recently acquired a Harrington & Richardson 5-shot 3" hammerless, top-break revolver chambered in .32 S&W. This caliber is sometimes (incorrectly) referred to as .32 "Short" to differentiate it from the already-descriptively-named .32 S&W Long. My particular revolver was made between 1896 and 1898, and was designed to shoot black powder cartridges.

These little top-break pocket revolvers are not particularly scarce or valuable, although the one I have is unusual because it is blued; while most examples were nickel-plated. It is also in exceptional condition, with no rust and about 98% of the bluing intact. It's very tight, and the bore is bright and mirror-like, which means that this revolver was well maintained and probably seldom used. I decided to change that (the "seldom used" part - I plan to keep it well maintained!)

Winchester (85gr LRN), Magtech (85 gr LRN), and Remington (88gr LRN) still make factory ammo in .32 S&W, however modern smokeless powder factory ammo is too powerful to use in top-break revolvers originally chambered for the black powder version of this cartridge. If I'm going to shoot this little revolver, it's going to have to be with ammo I make myself - which is good, because after all, this is an article about reloading.

Incidentally, I'm describing this caliber as "nearly" obsolete because the cartridges that were available when this revolver was made were loaded with black powder; they developed much lower pressure than any currently loaded factory ammo, and are no longer available.

I had several concerns about loading such a caliber for an antique firearm:

- The bore and chamber throats of the revolver might not meet SAAMI standards, because the gun

predates SAAMI by about three decades.

- Appropriate components and dies can be hard to find, especially if the gun doesn't conform to

SAAMI specs.

- There is no load data for .32 S&W in any of my manuals, and even if I found data, I wasn't sure

if it would be any good for a gun originally designed for a black powder cartridge.

Measuring the Throats and Slugging the Bore

Because this revolver was manufactured about 30 years before SAAMI was founded, I had concerns that the

chambers in my gun would not conform to SAAMI specs. The only way to find out was to make a few measurements.

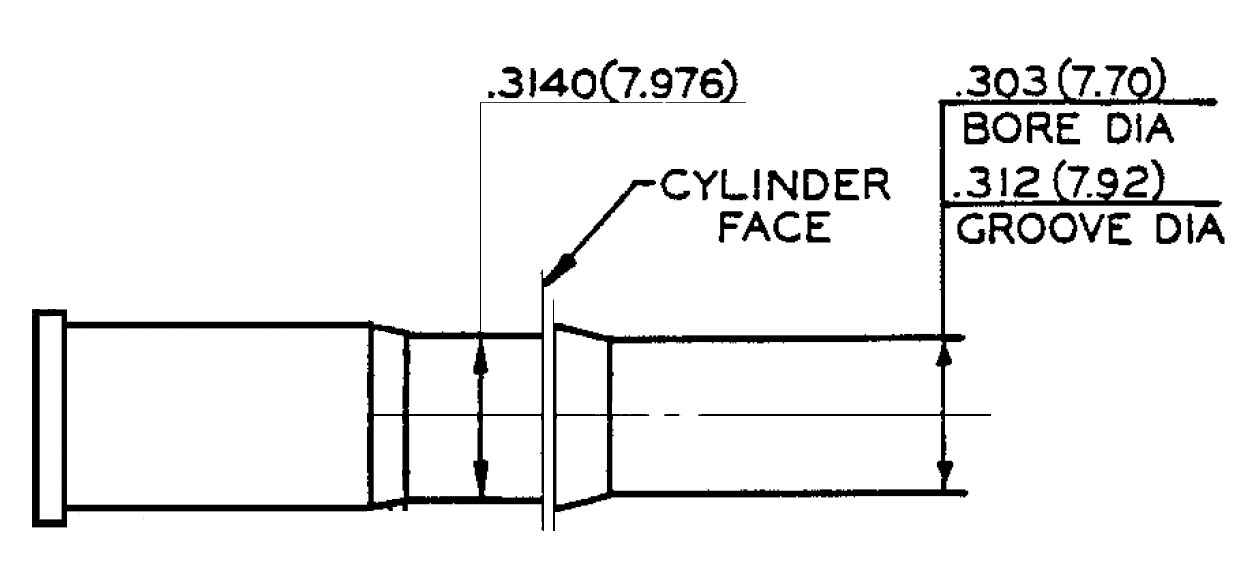

The drawing in Figure 3 shows some of the SAAMI chamber and bore dimensions for the .32 S&W.

For reloading, the most important dimensions are the bore's groove diameter (.312" according to SAAMI) and its relationship to the chamber throat diameter (.314" in the drawing above). Ideally, the chamber throat diameter would be larger than the bore groove diameter by about 0.001" to 0.002"; the reason being that if the chamber throat is smaller than the groove diameter, the bullet will essentially be "resized" to a diameter smaller than the bore as it is forced through the throat, and will then be undersized for the barrel.

When an undersized lead bullet travels down the barrel, the hot gases from the powder combustion escape at high speed around the sides of the bullet. These jets of hot gas "cut" lead from the sides of the bullet and deposit it into the bore ahead of the bullet. This results in barrel leading and greatly reduced accuracy. I had decided ahead of time that if the cylinder throats on my revolver were smaller than the groove diameter, it would become a display piece instead of a shooter. Obviously it worked out; otherwise this article would end here.

I measured the cylinder throat diameters using pin gages. Pin gages are precision-ground metal cylinders precisely sized to specific diameters, graduated in 0.001" increments. I used a 0.250" to 0.500"set of pin gages to check the throat diameters. Using the pin gages is simple: Select a gage and see if it fits in the hole. If it does, try the next size up. If it doesn't fit, try the next size down. Stop when you've found the largest pin gage that will fit, and you've found the hole diameter to within 0.001". The chamber throats on my revolver were a very consistent 0.315" - just 0.001" over SAAMI specs.

To measure the groove diameter, you need to "slug the bore". This involves forcing a slightly oversized soft lead slug through the bore, and then measuring the diameter including the raised areas created when the slug material was forced into the grooves. The bore on my revolver measured out at 0.313" - also 0.001" larger than SAAMI specs.

I lucked out. The throat size to bore size relationship should allow me to shoot this revolver without barrel leading.

Components and Dies

Because the throat and bore measurements worked out, this part was relatively easy. After a quick

search online, I was able to locate some Starline Brass cases and some 78 grain, 0.313" diameter cast

lead, polymer-coated bullets intended for .32 S&W Long. Because of the overzealous enforcement of

misinterpreted idiotic regulations in Massachusetts, I had to have these inert pieces of metal shipped

to a friend in NH where I picked them up.

As far as dies go, I considered cobbling together a makeshift set using a .32 H&R Magnum shell holder and sizing die, along with the expander and seat/crimp dies from a .32 ACP set. While looking online, I saw that Lee offers a carbide die set for .32 S&W, so I went with that instead. I should have trusted my first instinct because the Lee die set consists of the shell holder and sizing die from a .32 H&R Magnum, coupled with the expander and seating/crimping die from a .32 ACP set.

Load Data

This was also a bit easier than I thought it would be. I have the Internet to thank for the load data

for this cartridge. The Hodgdon website has data for an 85gr cast lead bullet with W231/HP-38. The Lee

2nd Edition manual lists the same load as the Hodgdon site, but none of the other reloading manuals in

my library have any data for the .32 S&W.

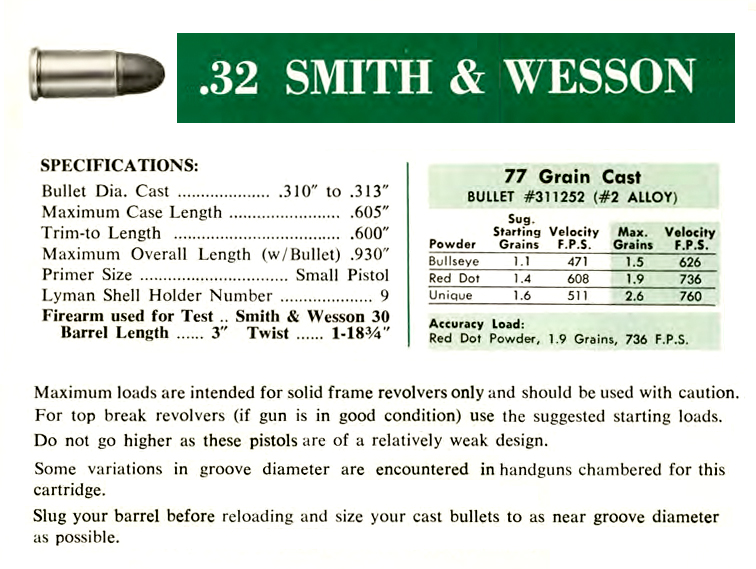

Figuring that at some point, somebody had to have published reloading data for the cartridge, I posted a request on a popular local firearms forum (NortheastShooters.com) and two members came through with data published in the Lyman 44th Edition in the 1960's (see figure 5).

This manual lists loads with several powders for both 77gr and 85gr cast lead bullets, and also provides this bit of advice:

"For top break revolvers (if the gun is in good condition) use the suggested starting load. Do not go higher as these pistols are of a relatively weak design."

In his book "Pet Loads", Ken Waters made a similar "stick-with-the-starting-loads" recommendation when loading for top-break revolvers that were designed for black powder cartridges. (By the way, if you reload "older" calibers and don't have this book, you should get it while it's still in print).

I had some of each powder on hand, but decided to go with Unique because I had good success in the past loading .32 ACP with it, and figured that the .32 S&W was a close match in terms of case volume.

I used CCI small pistol primers and loaded to a C.O.A.L. of 0.870", which aligned the crimp groove of the bullet to the top of the case. The seating/crimping die put a taper crimp on the cartridge. Normally you would want a roll crimp on a revolver cartridge, but the die in the set used a taper crimp, so I was stuck with it. In this case, a roll crimp wasn't absolutely required because there's hardly any recoil and the powder is fast burning enough to get going without a strong crimp.

I loaded my test cartridges on a single stage press and used a RCBS Uniflow powder measure (small version) to drop the charges, which it did consistently within .1 grains. I used the revolver's cylinder as a 'gage' to check the completed cartridges for fit as I went along. I loaded a total of 20 cartridges and couldn't wait to try it out.

Shooting It

I went to the range on Sunday in February - a day that had near-record cold. It was -6 degrees F when

I got to the range. I managed the 10-shot group shown in Figure 6 at about 10 yards.

The first three shots were low, so I applied Kentucky windage (or Kentucky elevation?) to correct for the rest of the shots. The revolver was WAY more accurate than I expected it to be. Make no mistake about it, this is a tricky gun to shoot. The sights are tiny, the grip is very small, and it has a long gritty double-action-only trigger. Even with these difficulties, I was able to keep the shots in a fairly tight group, which is a testament to the quality of this little revolver. If the flu didn't kill you, you got a lot for six bucks in the 1890s.

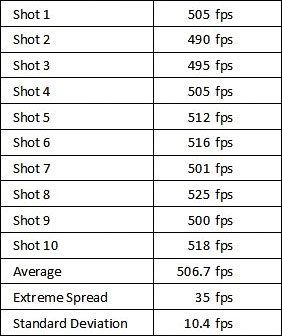

The chrono results are shown in Table 1:

After the shooting session, the revolver cleaned up quickly - in part because the cylinder comes right out. There was absolutely no trace of leading in the barrel - which is what I expected, based on the cylinder throat and bore measurements.

Conclusion

This was a very satisfying experience. I was able to take a >100 year-old, $6 revolver that

probably hadn't seen the outside of a sock drawer since the Taft administration, research it,

measure it, load for it, and safely produce a more-than-acceptable group out of it with readily

available components.

This illustrates one of the greatest benefits of reloading: It gives you the ability to continue to enjoy shooting classic firearms long after factory ammo becomes unavailable.

UPDATE:

If you're reading this because you clicked on a link from the Starline Facebook page, please be advised that their brass is OK (not as good as Jagemann),

however their customer service leaves a lot to be desired.

Without my permission, they've been using my website to promote their products on Facebook.

My only business is from local (to MA) in-person reloading classes, which fill up anyway, and manufacturing "boutique" ammo for sale (I'm an 07 FFL).

Their promotion really doesn't help me, it only helps them. Even so, I don't mind them doing it.

They do it a lot too. As of 8/2020 they've posted links on Facebook 14 times and counting!

Here's what bugs me: I've sent them no less than four customer inquiries, and they've ignored every single one. Every. One. I'm sure business is good right now (AUG 2020),

but ghosting prospective customers is bad, and we have long memories.