Why are Handloads More Accurate Than Factory Ammo?

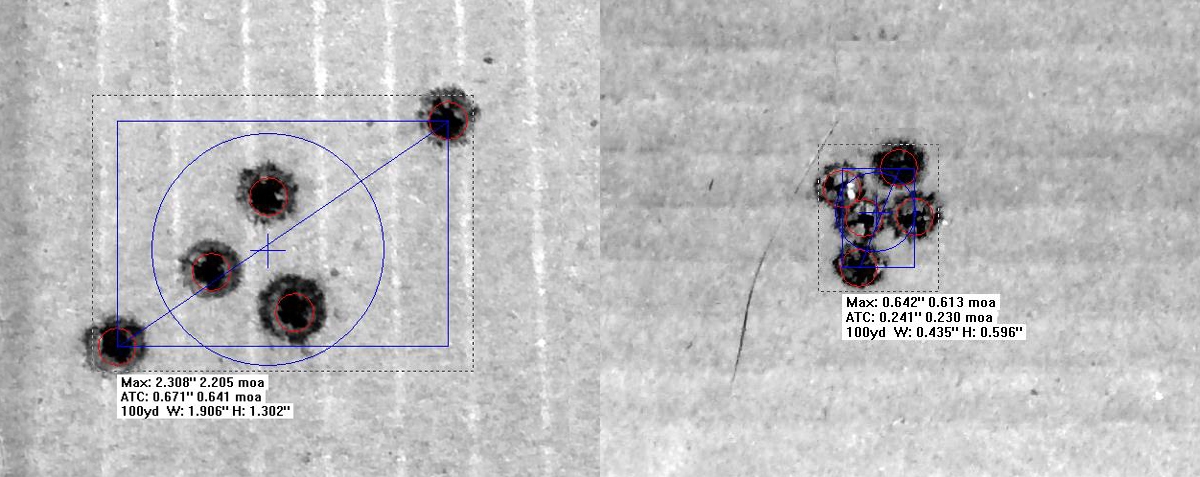

In the last article, I fired a series of five-shot groups with both factory and handloaded ammo to see which was more accurate. Predictably, the handloaded ammo produced smaller groups (see the best group from each in Figure 1). The difference in precision between the two types of cartridges was a bit of a surprise - the average group size for the handloads was around 0.6 MOA, while the factory XM193 ammo produced > 2 MOA groups. This month, we'll try to make some educated guesses as to why there was such a big difference.

I actually purchased two boxes of factory ammo for this test. I shot groups with one box, and reserved the cartridges from the second box to take a series of measurements that I hoped would help to explain the difference in group size.

Using these cartridges, I measured cartridge overall length (with and without a bullet comparator), and cartridge headspace length. I also took the cartridges apart and measured the powder charge weight, case length, bullet length, bullet weight, and case weight (with the primer). Based on these measurements, I was able to make an educated guess as to which factors caused the difference in precision. One item in particular stood out, and it's a very easy thing to correct when making your own ammo.

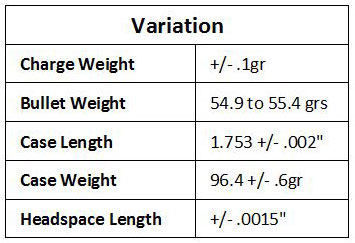

First, let's list some of the variables where the factory ammo was consistent. It is unlikely that ANY of the items in Table 1 below contributed to the inaccuracy of the factory ammo in a significant way.

The factory powder charge weights were nearly as precise as what I used in the handloaded ammo. The brass cases were also very consistent. The bullet weight variation was only slightly larger than what I measured in a sample of the match bullets used for the handloads.

With consistent charge weights, bullet weights, and cases, one would expect consistent velocity from the factory ammo as well. As it turns out, the velocity was quite repeatable with the factory ammo. The maximum measured velocity was 3410 FPS, the minimum was 3333 FPS. The resulting extreme spread of 77 fps would account for only about 0.1" of vertical shot dispersion at 100 yards. Clearly, something other than the velocity was to blame for the inaccuracy.

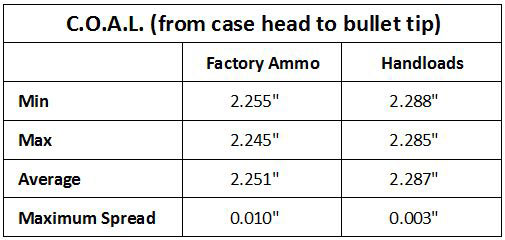

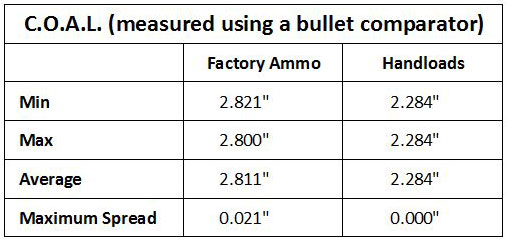

So what caused the difference in group size? The short answer is, "The bullets did, because they're not all the same shape." Table 3 shows the measurements of cartridge overall length for both the factory ammo and the handloads. This measurement represents the distance from the case head to the tip of the bullet.

The factory ammo exhibits significantly more variation in C.O.A.L. than the handloads - 0.010" compared to 0003" for the handloads. One possible reason for this variation could be that rough handling has caused the tips of the factory bullets to become slightly more deformed than the bullets in the handloaded ammo, and therefore "threw off" the measurement. After all, the factory ammo is military style "bulk" ammo - it's not as if the manufacturer treats it with kid gloves.

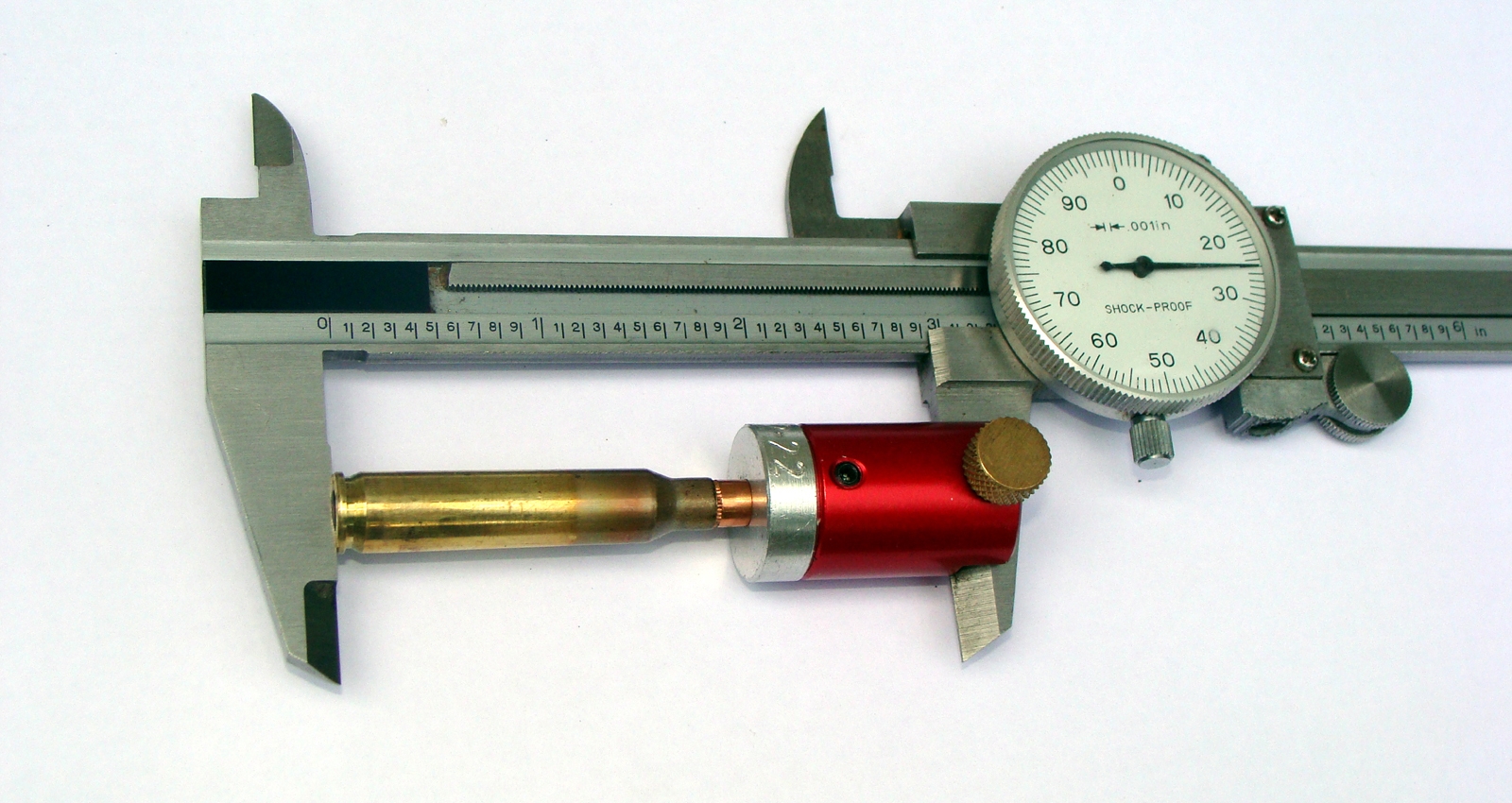

One way to eliminate the 'damaged tip' variable from the measurement is to use a device called a "Bullet Comparator". The bullet comparator is an adapter that fits onto a dial caliper that features a caliber-specific insert. The comparator and insert allow you to measure the cartridge overall length from the case head to the point on the bullet where the bullet's diameter equals the bore diameter (see Figure 2).

Table 3 shows the C.O.A.L. measure with the bullet comparator in place. Surprisingly, although this method of measurement eliminates variations caused by tip deformities, the factory ammo shows more than double the variability than with the 'raw' case head-to-tip C.O.A.L. measurement. Instead of improving, it got worse!

The only possible explanation for a greater length difference with the comparator than without is that the bullets themselves are actually different.

Inexpensive factory ammo is assembled using bulk bullets that were made by different machines, with different tooling, set up by different operators, on different days. Depending on the manufacturer, the bullets might even be from different suppliers. Even if the bullets are roughly the same nominal diameter and weight, variations in their shape will affect the seating depth, flight characteristics, the rate at which they lose velocity, and ultimately their point of impact on the target.

The match bullets that I used in the handloads are all from the same lot, made by the same machine, on the same day. I seated the bullets using a competition seating die that inserts the bullet into the case by pressing on the ogive rather than the bullet tip. The end result is extremely consistent C.O.A.L. as measured with the bullet comparator. There was literally no measurable variation in the comparator length of the handloads.

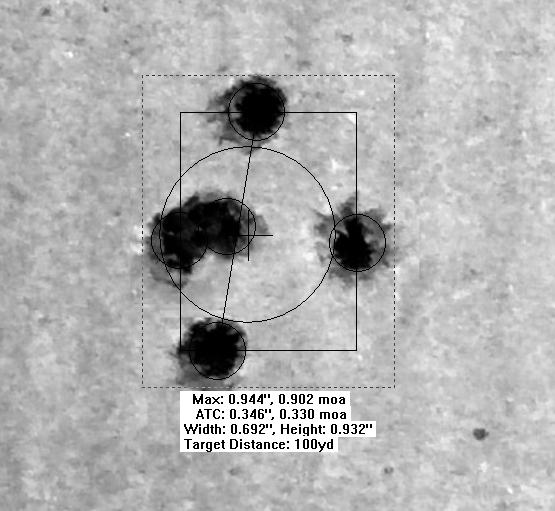

To test this hypothesis, I neck-sized some of the disassembled factory cases, and then reassembled five rounds using the original powder, but replaced the factory 55gr FMJ bullets with Berger 52Gr match bullets; which I seated to a C.O.A.L. of 2.250" with a competition seating die. Figure 3 shows the resulting group from the 'new' factory ammo.

By changing nothing but the bullet (and possibly the seating depth), I was able to shoot a sub MOA group with factory ammo that previously produced group sizes in excess of 2 MOA.

An interesting experiment might be to take a larger quantity of factory ammo try shooting some groups using rounds that were sorted first by comparator C.O.A.L. and then by case head-to-bullet tip C.O.A.L. Sorting them in this way makes it likely that each 'batch' of cartridges will have the same (or similar) bullets.

For the handloader, this exercise reinforces the notion that good bullets make good ammo, and that even carefully weighed powder charges and properly

prepared brass cannot compensate for inconsistent bullets.

The best route to making match-quality ammo is to use match-quality bullets.