Turret Presses

I have to be honest here… I had been putting down turret presses for years. My contention was, "The only benefit of a turret press is the ability to quickly change dies. If you have a single-stage press equipped with a quick-change system like the Hornady Lock-N-Load or Lee Breech Lock, there's not much additional benefit to reloading on a turret press."

I was wrong.

After I expressed the opinion above on a local online shooting forum, somebody (rightfully) cyber-slapped me with this: "The main benefit of a turret press over a single stage has nothing to do with quick die change; its benefit is the efficiency increase you get from not having to handle the cases as much." As it turns out, the comment was perfectly timed for me to have an epiphany - I had just labored for more than four hours to load 200 rounds of S&W 500 Magnum on a single-stage press, and I was trying to think of a better way to load this caliber (and the .460 S&W) without investing over $450 in Dillon 650 caliber conversions, toolheads, and special parts for calibers where I use less than 1500 rounds per year.

I decided to try a turret press.

"Traditional" Turret Presses

Like a single-stage press, a turret press performs work on only one case at a time. In fact, turret and single-stage presses use the same shell holders. However, where a single stage press has only one hole in which to put a die, a turret press has a disc-shaped turret on the top that can hold anywhere from three to seven dies depending on the model. (NOTE: You can find used examples of old turret presses that have the ability to hold up to twelve dies!).

On a "traditional" manually indexed turret press, the turret is attached to the main casting by a large bolt in the turret's center. In addition to attaching the turret to the casting, the bolt serves as the 'axle' around which the turret can rotate. There is a handle on the turret that enables the operator to rotate it in order to position different dies above the shell holder. Most turret presses also have some sort of a primer arm that you can use to prime cases on the press.

A turret press can be used like a single-stage press to batch-process cartridges: Resize all the cases, then index the turret to the expander die and expand all the cases, then prime and charge them, and finally index the turret again to the seater/crimp die and run them through once more to finish loading. If used this way, the output of the turret press is not much better than a single stage press.

Another way to use the turret press is to load each cartridge sequentially - in other words, start with a single case and sequentially perform all the steps needed to completely load the cartridge - resize it, rotate the turret to the expander die and expand it, then prime and charge the case, then place a bullet on top, rotate the turret to the seating/crimping die and finish it up; repeating as needed. This is faster than batch processing because you need to place/remove the case from the shell holder only once instead of three times while batch processing.

You can also use the turret press with a hybrid sequential-batch reloading process. This is the way I ended up doing it, and I found it to be about three times as efficient as loading on a single stage (see my description below).

Which Press?

I was looking for a press that had at least 6 positions for reloading dies. After reading the online reviews and talking to other reloaders, I narrowed my choices down to the Redding T-7, the RCBS Turret Press, or the Lyman T-Mag 2. All three received excellent reviews, and were priced with $50 of each other. After getting a look at the three machines in person, I chose the Redding T-7. While I'm sure the Lyman and RCBS are excellent presses, the Redding is like a whole different class of machine. Look at them together and you'll see what I mean. The Redding is MUCH beefier, and features a turret that holds up to 7 dies as compared to the 6-die capacity of RCBS and Lyman presses. This ended up being a big deal for me (keep reading and you'll see why).

I purchased the optional Redding "Slide Bar Primer Feeder System" which is a manually operated primer feeder arm with a magazine tube similar to the ones you find on progressive presses. However, I ended up taking it off the machine because I was able to reload quicker without it. It mounts directly in front of the ram, so it's constantly in the way, and since it requires you to manually operate the slide to put the primers in place, it ends up being not much faster than manually priming the cases off the press.

The "Hybrid" Process

I'm using the turret press to load both S&W .500 and S&W .460 Magnum cartridges. With the Redding T-7, I'm able to keep both sets of 3 dies installed in the turret at all times, and I put a Hornady L-N-L case-activated powder measure in the remaining (7th) hole in the turret. I would not have been able to do this had I opted for the RCBS or Lyman press.

Here's how I have things arranged in the seven stations of turret (See Figure 2):

1 - S&W .500 sizing die

2 - S&W .500 expander die

3 - S&W .500 seat/crimp die

4 - Powder die (Fits the Hornady case-activated powder measure)

5 - S&W .460 seat/crimp die

6 - S&W .460 expander die

7 - S&W .460 sizing die

Here are the reloading steps for S&W .500 with this setup:

- Locate the resizing die (Station 1) above the shell holder, and place the case into the shell holder with your left hand.

- Pull the handle to resize the case with your right hand.

- As soon as the case mouth clears the decapping pin on the way out, index the turret one position to the right. (Station 1 to Station 2) with your left hand to position the expander die over the shell holder and run the case right back up into the expander die. Repeat these three steps for the whole batch of cases.

- Prime the cases off the press with either a hand primer or bench-mounted priming tool.

- Locate the powder measure (Station 4 ) above the shell holder, place a primed case in the shell holder with your left hand, and pull the handle with your right hand to charge the case. As soon as the case clears the powder measure on the way out, index the turret one position to the left (Station 4 to Station 3) with your left hand to position the seat crimp die above the shell holder.

- Place a bullet on the case with your left hand, then run the cartridge up into the seat/crimp die.

- Remove the finished round. Repeat these steps for the rest of the cases. For S&W .460, the sequence would be Station 7 to Station 6 for sizing and expanding, the Station 4 to Station 5 for charging and seat/crimp.

It may seem complicated at first, but with a little bit of practice, the process goes very quickly. Using this method, I was able to load 100 rounds in about 40 minutes without rushing.

Incidentally, the S&W 500 case (1.625" length) is shorter than the S&W .460 case (1.800" length). So, rather than readjust the height of the powder measure when switching from one caliber to the other, I ordered an extra powder drop sleeve for the Hornady case-activated powder measure ($8) and shortened it by 0.175" in a lathe. The drop sleeve is a sort of a funnel that fits inside the powder measure, between the bottom of the powder drop and the case. When I'm loading .500, I use the stock sleeve, when loading .460 I switch to the modified one. This way, a quick swap of the powder sleeves allows the bottom part of the powder measure (that screws into the die hole in the turret) to stay at the same height for both cartridges.

Auto Indexing Turret Press

You might've noticed that throughout this article, I've been referring to the Redding, RCBS, and Lyman presses as "traditional" turret presses. This implies that there must also be a non-traditional turret press. There is; and it's called the Lee Classic (4-Hole) Turret press. I excluded the Lee from my initial search because it has only four die positions, but I ended up getting one anyway for a different application.

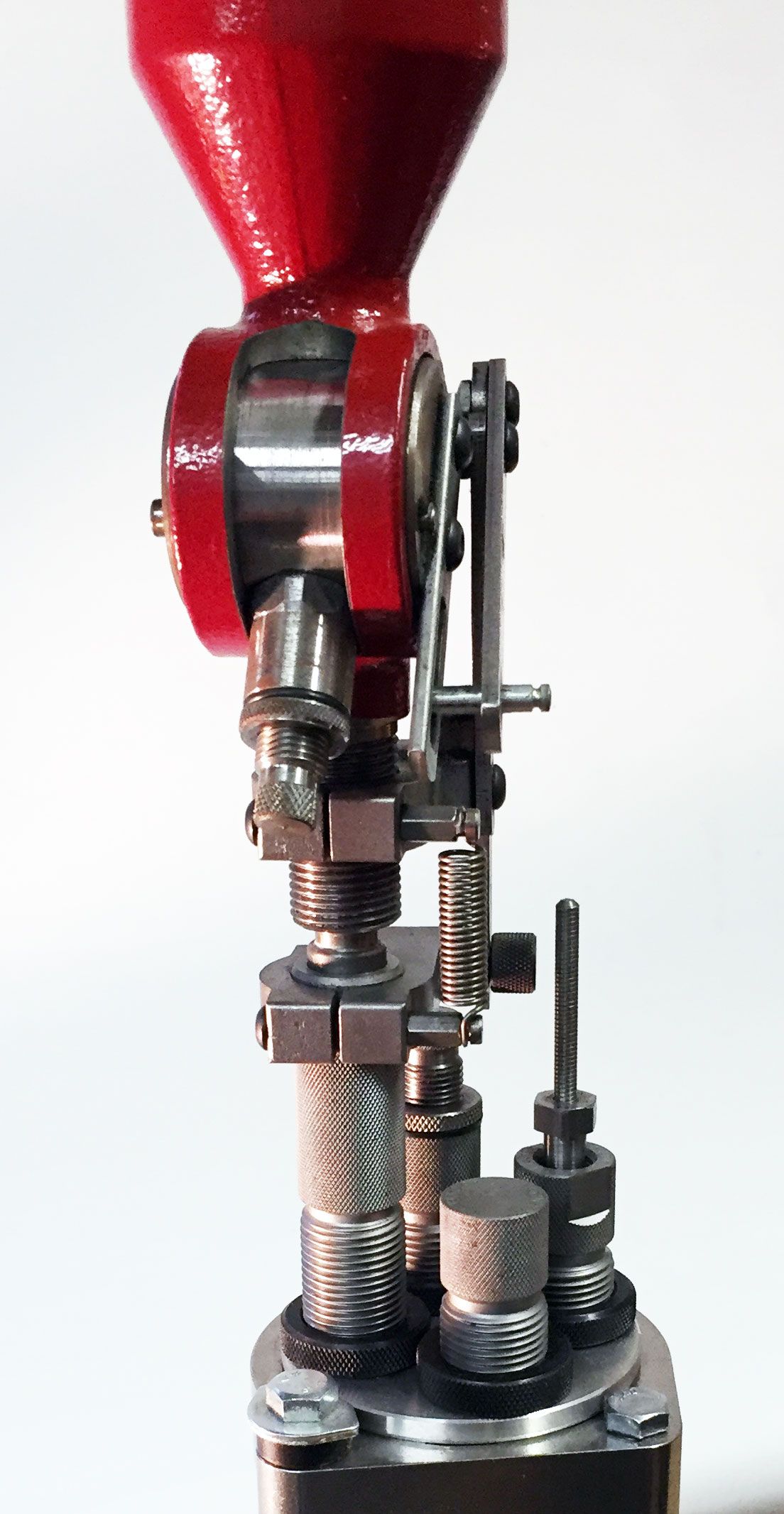

Unlike traditional turret presses, the turret on the Lee press is substantially smaller in diameter, and held onto the main housing of the machine by an annular ring around the outside of the turret. The turret is held into the ring by a series of locking lugs that are similar in look and function to those on an AR-15 bolt. As stated earlier, the turret has places for up to 4 dies, and is made from aluminum (see Figure 3).

The press features a square indexing rod with a 90-degree twist in it. One end of the rod is attached to the exact center of the turret; the other end goes into a hole in the press's base where it is free to rotate (see Figure 4).

There's a follower around the outside of the rod that is attached to the ram of the press, just below the shell holder. Every time the ram is lowered, the follower rides on the indexing rod, twisting it 1/4 turn, which rotates the turret 90-degrees. Since the turret has 4 equally spaced die holes, each ¼ turn positions the next die over the shell holder. It's an ingenious design, and I like it. I plan to do a more thorough review on the Lee Turret Press in a future article.