Giraud Powered Case Trimmer

If you ask a reloader to name the most tedious part of rifle case prep, more often than not, the answer will be, "Trimming." Case trimming is necessary because bottle neck rifle cases stretch slightly when you fire them, and again when they are full-length resized. So, the neck of each freshly-prepped case will be longer than it was before it last fired. If the case stretches to the point where it exceeds the SAAMI maximum length limit, it must be trimmed or the resulting cartridges will either not chamber or will produce unsafe pressures when fired.

You'll also achieve the best accuracy if you trim each batch of cases to a uniform length the first time you prep them. Even new cases can sometimes benefit from a slight trimming before you load them. In addition to making them a uniform length, a quick trimming will clean up any case mouths that are left rough from the manufacturing process, resulting in easier bullet seating and better accuracy.

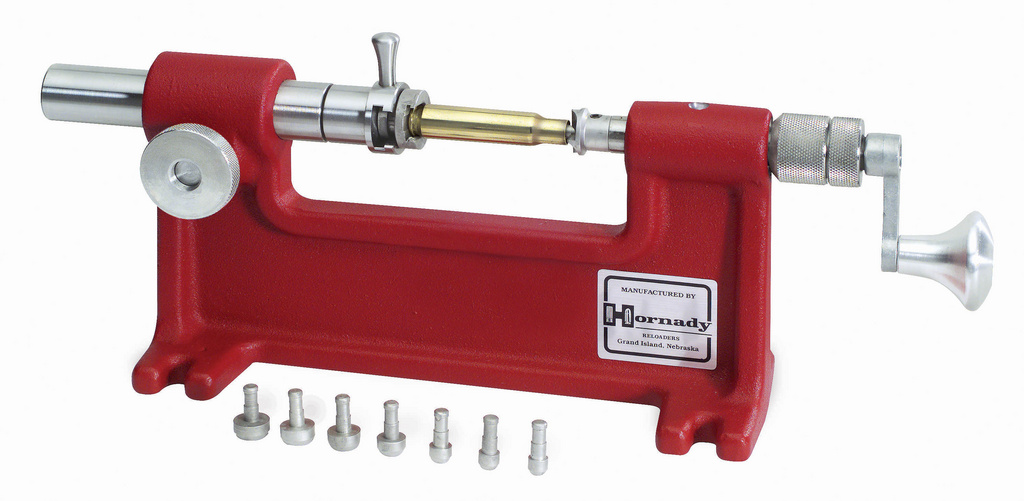

Manual Trimmers

The most common style of case trimmer resembles a small metal lathe (See Figure 1). There is a collet at one end to hold the case, and a cutter at the other to

trim the neck. You simply set the trimmer for the proper length, mount the case into the collet and crank the handle until the cutter stops cutting.

After trimming, the case mouth will have sharp edges on the inside and outside that must be removed in a separate step using a chamfer/deburring tool.

The whole process is time consuming, but not particularly onerous if you're trimming a small quantity ( less than 100) of cases. Many of these trimmers are available with adapters that allow you to replace the hand crank with a power drill. This can speed up the process a bit, but the real time-consuming part is mounting and removing the cases. The practical production limit for these devices (including the separate steps of chamfering and deburring) is about 250 cases per hour.

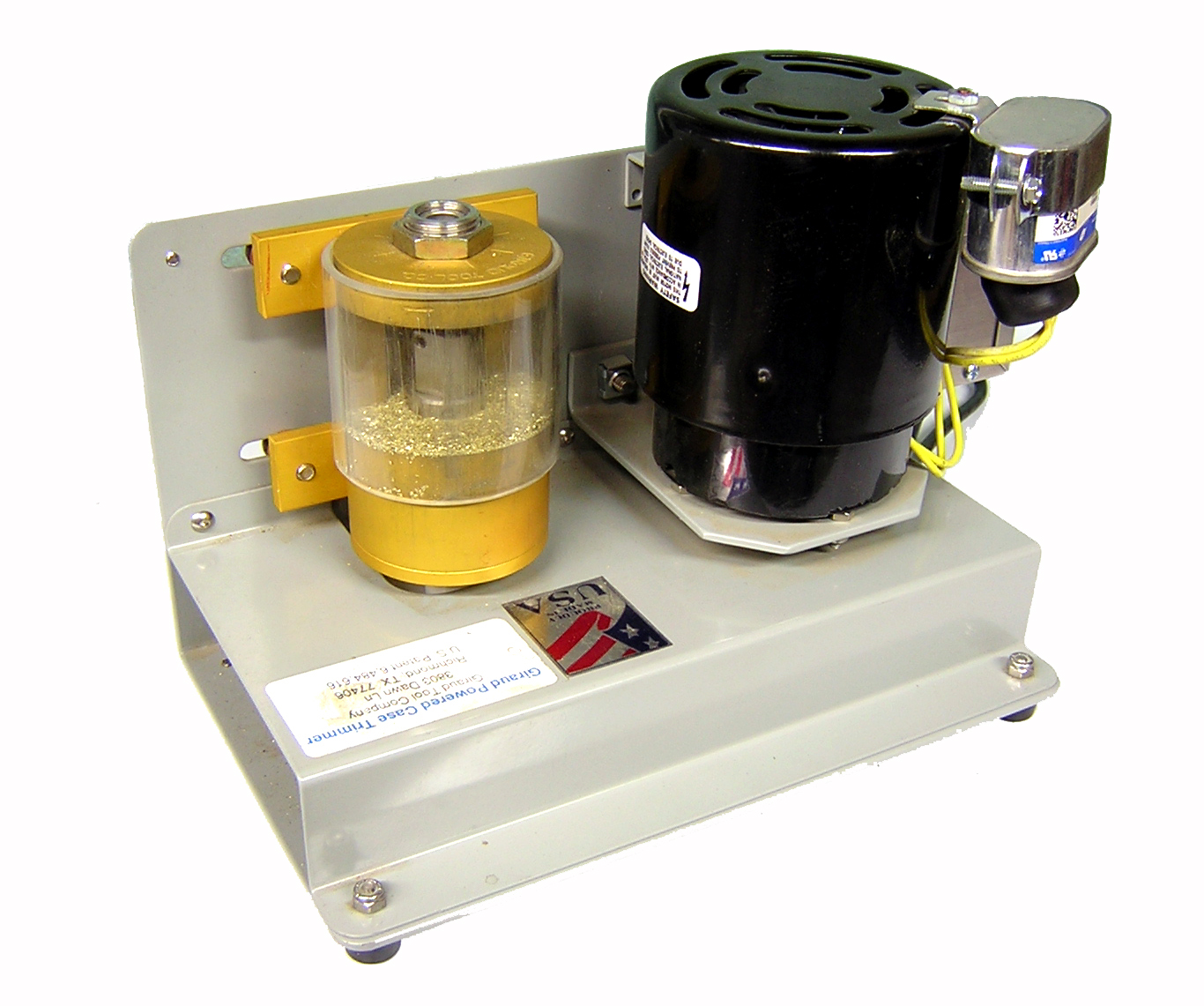

The Giraud Power Trimmer

For high volume trimming, nothing beats a Giraud (pronounced Jeh-ROE) trimmer. The Giraud is a motorized power trimmer capable of trimming, chamfering,

and deburring up to 1500 cases per hour.

The Giraud trimmer is a solidly-built American made trimmer designed and manufactured by the Giraud Tool Company of Richmond, Texas. The trimmer features a 1/8 horsepower induction motor that drives a ball bearing supported carbide tipped cutter head via a cogged timing belt.

The heavy-gauge sheet metal base allows you to use the trimmer vertically (with the cutter pointed up) or horizontally. If you like to stand while you trim, the vertical position works best. If you prefer to sit, then it's easier to use the trimmer with the cutter oriented horizontally.

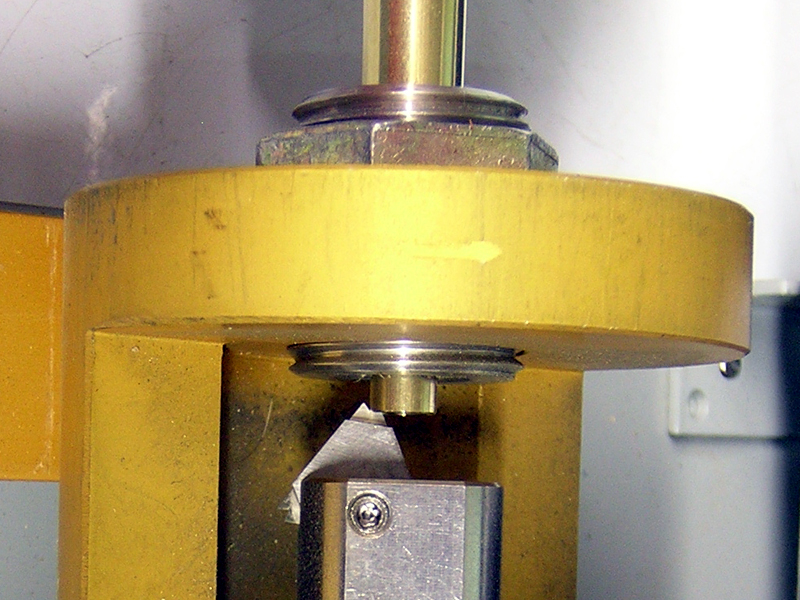

The cutter head assembly is made from machine gold-anodized aluminum. It features a clear Lexan chip shield that keeps all of the brass shavings inside the machine. To empty the shavings, simply bring the whole unit over to a trash barrel, slide the shield back, and give it a shake.

The cutting blade is mounted in the cutter head offset from center by a distance equal to the radius of the case mouth. When the cutter head spins, the cutting edge rotates around in a circle equal to the diameter of the case. The cutting edge itself is V-shaped. This enables the cutter to trim the case to length, and at the same time deburr the outside and chamfer the inside edges of the case mouth.

During trimming, the case is held in a caliber-specific collet that is machined to match the case like a rifle chamber. The collet is spring loaded. To trim a case, simply insert a case into the collet and push it down until it contacts the spinning cutter. The trimmer stops cutting when the case is trimmed to the preset length. If you can use an electric pencil sharpener, you can use a Giraud trimmer.

The "trim-to" length can be adjusted by loosening the collet lock nut and moving the collet closer to, or farther away from the cutter. Both the collet and base have witness marks, so it is easy to see how much you're moving it.

Caliber changes are straightforward: First, select a couple of ‘sacrificial' cases. Install the appropriate collet, loosen the set screw on the cutter head, push a case into the collet and move the cutter so that the edge of the case mouth is in the center of the V-shaped cutting edge. Tighten everything up and test it, then make any necessary adjustments through trial and error. With practice, you can change calibers in about 5 minutes.

Giraud offers extra complete cutter heads for reloaders that would prefer to swap out the entire cutter assembly rather than adjust the cutter position on caliber changes. I don't find the process of moving the cutter particularly difficult, so I use the same head for all calibers.

The cutter itself is made of long-lasting carbide. It is triangular shaped with three cutting edges. When one becomes dull, you can remove and rotate the cutter 120 degrees to bring a new cutting edge to bear.

In addition to being fast, the Giraud trimmer is accurate. My experience has been that with properly sized cases, the trimmer will cut them all to within 0.001"of the same length. Since the Giraud trimmer indexes of the case shoulder rather than the case head, extra care must be taken during the sizing operation to ensure that the shoulders are all pushed back the same amount. If not, you will see greater variation in finished case length. This will usually only occur if you are trimming cases that were sized using multiple setups. If you size a large batch of cases with a single setup, they should all trim to the same length.

Another often overlooked reason that the Giraud is more accurate than lathe-style trimmers is the fact that the Giraud automatically chamfers the inside of the case as it trims. This results in inside chamfers that are extremely consistent and uniform. With manual trimmers, the chamfer must be performed as a separate manual operation. When chamfering by hand with a manual deburring/chamfering tool (see Figure 4), it is impossible to maintain consistency. This may seem like a small matter, but consider that any material removed during chamfering effectively shortens the bullet holding portion of the case neck.

As a test, I slowly and carefully hand-chamfered a group of 20 cases that were trimmed to exactly the same length, and measured the chamfer depth using a single reference bullet and a bullet comparator mounted in a dial caliper. I found an extreme spread of 0.006" in chamfer depth. I can only imagine what they've been on the not-so-carefully chamfered cases I've loaded in the past.

The Giraud trimmer is pricey. The list price for the trimmer configured for a single caliber is $440 plus shipping. Collets for additional calibers are available for $30 each. I wanted one of these for a long time. I even tried to get some friends that reload to split the cost and share it. Finally, after trimming a batch of 2000 .223 cases (and waiting for the blisters to heal) I went online an ordered a Giraud, and I haven't regretted it.

This trimmer is designed to last a lifetime. I've trimmed upwards of 50,000 cases on mine, and it is still going strong. In addition to .223, I've since purchased case holders for 6.8 SPC, .308, .30-06, and 7mm Magnum, and have collets for .25-20 and .300 Blackout on order. In my opinion, this trimmer is worth every cent I paid for it. If I ever decide to get rid of it, my total investment will have been minimal, as used examples are selling for >95% of the retail price.