Rifle Cartridge Overall Length

An important part of fine-tuning a rifle load is finding the bullet seating depth that results in the best accuracy. Much like determining the optimum charge weight, finding the best seating depth is done through trial and error testing. Unlike the optimum charge weight - which is a powder charge weight that will shoot well out of a variety of different rifles - the correct bullet seating depth is very rifle-specific. More than anything else, the cartridge overall length is what will 'personalize' a particular load for a particular rifle.

Stating that a certain bullet seating depth will result in more accurate ammo implies that there is a range of seating depths (or cartridge overall lengths) available to the reloader for any given cartridge, much like there is a range of charge weights available for any given cartridge/powder combination. However, unlike the charge weight information, not all of the cartridge overall length (or COAL) information can be found in reloading manuals.

The cartridge overall length specified in the reloading manuals for a rifle cartridge is usually the minimum length for that bullet/powder charge combination. Staying at or above this minimum will not cause an over-pressure condition (in most cases - read the warnings below). Going shorter than the minimum length will seat the bullet deeper into the case, effectively decreasing the case volume and increasing the pressure. This practice is therefore not recommended.

Since the minimum length for your testing will be the minimum C.O.A.L. as specified in the manual, the question becomes, "What is the maximum length?" The maximum cartridge length will be determined by three factors:

Factor 1: The bullet must be seated far enough into the neck to provide sufficient hold.Factor 2: The cartridge should fit into the rifle's magazine (if it has one)

Factor 3: The bullet should be seated far enough into the case so that it does not contact the rifling lands in the barrel when the round is chambered.

Let's take these one-at-a-time:

Factor 1: A good rule for most applications is that a bullet will be sufficiently held in the case if it is seated so that at least one caliber's depth of the full diameter portion

of the bullet is seated into the case neck. For example, if you were loading a .308" diameter spitzer bullet, the minimum seating depth would be the length of the boat tail

portion of the bullet, plus .308". Please note that there are exceptions to this rule - there are some cartridge/powder/primer/rifle combinations that will shoot best with the

bullet seated shallower than a caliber diameter, but these are the exception, and you'll know it when you see it.

Factor 2: If your rifle has an internal or external magazine, and you plan on using it to feed cartridges into your rifle, the cartridges must be short enough to fit into it. You do have the option to load longer than magazine length. In fact, many of the heavier 'very-low-drag' (VLD) bullets for rifles like the AR-15 are too long to be loaded to magazine length. However, cartridges loaded with these bullets (or any cartridges longer than magazine length) must be single-loaded.

Factor 3 is the tricky one. You can use simple measuring tools to ensure that the bullet is seated to at least one caliber depth, and that the cartridge will fit into the magazine. However, additional tests are required to measure the distance to the lands for a particular rifle and bullet.

Measuring Maximum C.O.A.L.

You need to measure the maximum cartridge overall length that will fit into your rifle chamber with the exact bullet you will be loading. Old-timers (and those that are more frugal) do this by loading a series of dummy cartridges to various lengths, 'smoking' the bullets with a candle flame (to coat them with soot), chambering the dummy cartridges in the rifle, then removing them and looking for marks from the rifling on the bullets. The maximum COAL will be the longest cartridge without marks on the bullet. This process is time-consuming, wasteful, and not as accurate as a method that will make it easy for you to perform the test multiple times.

An easier way requires you to get three items: A cartridge overall length gauge (such as the one made by Hornady), a specially modified case for the caliber you will be loading, and a bullet comparator.

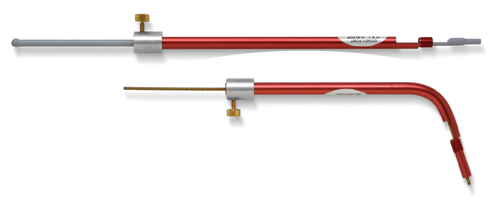

The overall length gauge is a hollow tube about 8" long with a threaded end. Inside the tube is a thin pushrod longer than the tube that can be locked into place with a thumbscrew. The overall length gauge is used in conjunction with a specially modified case in your caliber. This modified case has a large threaded hole in place of the primer pocket which allows the case to be fitted onto the threaded end of the overall length gauge.

To use the gauge, affix the modified case onto the threaded end, slide the pushrod up into the case so that the end of the pushrod is near the middle of the case's shoulder, and place the bullet you will be loading into the case neck. At this point, the test bullet will be 'seated' much deeper than normal. The case is sized so that the bullet is a slip-fit in the neck. Remove the bolt from your rifle and push the gauge/case/bullet into the chamber until it is fully seated. While holding the case firmly in the chamber, use the pushrod to shove the bullet into the barrel until it stops, then tighten the thumbscrew.

If you cannot get easy straight line access to your chamber (such as with a lever gun), a curved version of the OAL gauge is available that can be inserted through the ejection port of the rifle. (This is shown in the bottom of Figure 1 above).

Remove the gauge from the chamber. If the bullet does not come out with it, poke the bullet out of the barrel with a cleaning rod, and re-insert it into the modified case. The pushrod will stop the bullet and your resulting COAL will be where the bullet hit the lands. There is a cutout on the OAL gauge to allow you to get a caliper blade against the case head. Measure the distance from the case head to the tip of your bullet. This is your maximum COAL.

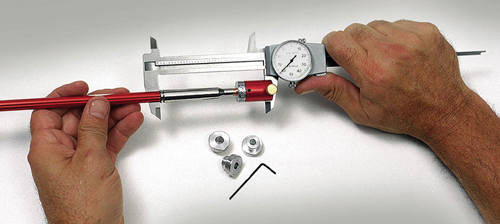

Unfortunately, simply measuring from the case head to bullet tip is not quite accurate enough. The tip of a rifle bullet is the weakest and most easily deformed part of the bullet. Bullet tips are deformed slightly during manufacturing, shipping, and handling; and they are not consistent enough for accurate measurement. This is particularly true for soft point or polymer tipped bullets (pointy polymer tips especially - they're deformed by the caliper itself when you try to measure them). This problem is solved by the third tool mentioned above: the bullet comparator. A bullet comparator consists of a spacer that is attached to the fixed blade on a dial caliper. The spacer uses caliber-specific inserts. The inserts feature a hole that is sized so that the caliper will measure at a point along the ogive (curved portion) of the bullet. This is much more consistent than measuring the tip.

Using the OAL gauge, modified case, and bullet comparator, you should test several bullets from the same batch you will be loading to determine the COAL where the bullets hit the lands in your rifle.

NOTE: You will have to perform this separately for each rifle you will be loading for, and for each different bullet that you will use. There is one important exception regarding COAL testing: Weatherby rifles and cartridges. When loading Weatherby magnum cartridges, you should always use the exact COAL specified in the reloading manual. Weatherby magnums require a certain amount of jump (freebore) before the bullet hits the lands. Failure to provide this will result in dangerous pressures.

Testing

You now have a range of COALs that you can use for testing. The minimum length is the COAL specified in the reloading manual. The maximum COAL will be whichever of the three factors described above that produced the shortest cartridge. For semi-auto, lever, and pump-action rifles, the bullets should be loaded no closer than 0.010" 'off the lands'; in other words, make your maximum COAL 0.010" shorter than the length you measured with the OAL gauge. Loading any closer to the lands on these rifles can cause feeding problems. For bolt action rifles (with the exception of Weatherbys), you can load right up to the lands. However, doing so will result in higher pressure,

so if you are loading to the lands, you should reduce your loads to the minimum and work up from there, looking for pressure signs along the way.

Divide your COAL range up in 0.005" increments, use the same bullet comparator that you used in the OAL test to set up your seating die, load a series of cartridges at each length, and shoot some groups. You should be able to determine the COAL that produces the best accuracy.

Final Thoughts

Fine-tuning the COAL is an important part of obtaining the best accuracy from your reloads. Many shooters feel that it has almost as much of an impact on group size as the powder charge. It is important to note that if you use a bullet comparator to measure your maximum COAL. You will need to use the same comparator to set up your seating die and measure the COAL of your reloads. The comparator's measurements are relative - it measures to an arbitrary point on the bullet ogive. If you use a comparator for one measurement and not for another (or use different comparators for each measurement), you will introduce significant errors in length that could lead to unsafe pressures